FST JOURNAL

Hardtech

DOI: https://www.doi.org/10.53289/WDLC2154

Understanding the manufacturing scene today

Peter Marsh

Peter Marsh is a writer and lecturer on 21st century manufacturing. He is the founder of Made Here Now, a website on UK manufacturing aimed at encouraging more young people to consider technology and production as a career. He previously worked at the Financial Times, most recently as manufacturing editor, and at New Scientist. He has a degree in chemistry from Nottingham University. In recent years Peter has given talks on manufacturing opportunities in countries including South Korea, Italy and Brazil.

On a matter of definition, ‘hardtech’ simply means using technology, or combinations of technologies, to make tangible products. Softtech, on the other hand, involves using technology in an intensive way to make intangible items.

At its most basic, manufacturing is about adding value to materials: it is really no more complicated than that. Looking at the Periodic Table of the elements, it is clear that there are only 100 basic materials to work with (if you leave out those that are quite hard to isolate). From those 100, the world's manufacturers make around 10 billion products every year, things that are vital to just about every part of life.

All of that is done by really quite a small number of people. In the UK, we are used to thinking we do not have many people working in manufacturing. Yet that is true this around the world. Manufacturing employs only about 350 million people globally, something like 10% of the available workforce. Approximately 15% of total global GDP is accounted for by manufacturing. The figure is about 10% in the UK. In only a handful of countries is manufacturing more than 20% of the economy. Britain is not such an outlier as some people think.

The people working in manufacturing generally need high levels of skills. The sector is a big user of technology and takes up nearly half of the total R&D in the UK. It therefore requires high levels of capital. If you put more into anything, more energy, ideas, etc, you should get more out of it. The same goes for manufacturing. Productivity in manufacturing is 10-20% more than in many services. For a sector employing relatively large numbers of skilled people, wages are also 10% higher than in much of the rest of the economy.

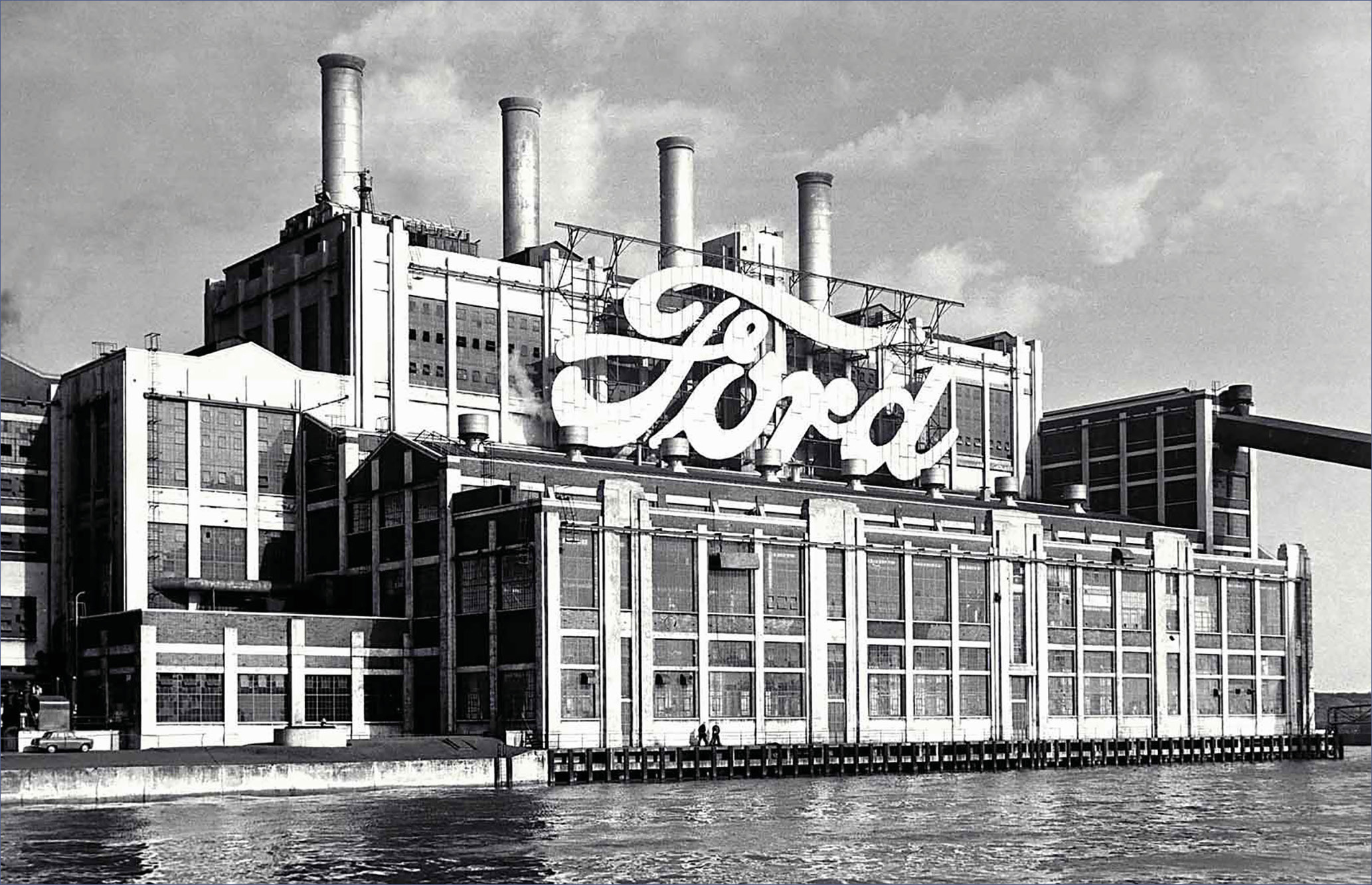

This may explain why manufacturing is – or at least should be – near the top of the priority list for politicians and others. Historically, Britain has had a very long involvement with manufacturing: it was, after all, the place where the original industrial revolution happened. For a brief period, (perhaps only about 50 years) it was the world's biggest manufacturing nation, accounting for about 20% of total manufacturing output in 1895. As recently as the 1950s, it was still high in the league table with 10% of total manufacturing output and seven or eight million people employed in manufacturing back then. Today, that figure has dropped to two and a half million and the United Kingdom is No 9 in the world league table. That falls to No 26 in manufacturing output per person, though.

Big factories used to be in every city, making steel, cars, ships: everyone could understand. Today, the typical manufacturing employer is much smaller, employing perhaps 100 people in a small building on the edge of town.

Big factories used to be in every city, making steel, cars, ships: everyone could understand. Today, the typical manufacturing employer is much smaller, employing perhaps 100 people in a small building on the edge of town. That paints a picture of relative national decline. There is a feeling that Britain used to be much better at this. There is still a feeling of nostalgia for the time when the country was No 1, it is part of our industrial history. On one level, then, there is a theory that it would be good if Britain could get back into a higher position in manufacturing, although there are doubts that it is achievable. At the same time, though, many people think of manufacturing as dirty, old fashioned and rather polluting and believe it is better that we do not do much of it.

Modern manufacturing

One of the problems about explaining the importance of manufacturing to politicians or the person in the street is a difficulty in describing what modern manufacturing is. The big factories used to be in every city, making steel, cars, ships: everyone could understand. Today, the typical manufacturing employer is much smaller, employing perhaps 100 people in a small building on the edge of town. They will be making, in many cases, obscure components for other more complex products. Explaining the reality of 21st century manufacturing is, therefore, very much needed.

Sales of manufactured goods in 2021 in the UK came to approximately £400 billion. Of this, 60% were standard industrial products, involving a modest level of technology – sectors like food, textiles and basic building products. Most of these are for domestic use. The remaining 40% is hardtech. The sectors include a range of industries, chemicals, industrial, scientific instruments, machinery, etc. Only half of this amount would be construed as advanced manufacturing or high tech, things like electronics, biotech and so on. The phrase ‘hardtech’ is therefore a much more useful concept here.

One reason is that there are excellent hardtech companies which would not fall within so called ‘high tech’, or advanced manufacturing. Renishaw, the metrology and healthcare technology group, employs 3,000 people. Brompton Bicycle has an annual turnover of £120 million. James Walker Group employs 2,000 people, half of them in the UK; they are specialists in sealing technology, rail track fixation and vibration attenuation.

A common feature of all these companies is the application of IT and automation. However, the main reason that they are successful and worth supporting is because of what they are doing in other areas, not IT. The ‘fourth industrial revolution’ is bandied about a little bit too much and is not a sufficient description of what is really going on. Policymakers need to understand that reality and then think about how best to help these companies.